Robust Joint Design for Ultrasonic Welding of Plastic Parts

While the concept of ultrasonic welding is simple, the process of designing a robust joint and developing an effective weld process can be quite complex. Typically, it starts with a nominal joint design, a nest and horn design, and the energy coupler gain to obtain the nominal vibration amplitude at the welded surfaces. Then, the process iterates between adapting the geometry of the joint and optimizing the weld process parameters (energy coupler gain, energy and energy envelope, pressure, and duration).

To create a good weld, the parts must make initial contact over a relatively small area compared to the finished weld area. This allows initiation of melting soon after ultrasonic vibrations are applied.

There are two common approaches for creating the small initial contact area: an energy-director joint and a shear joint.

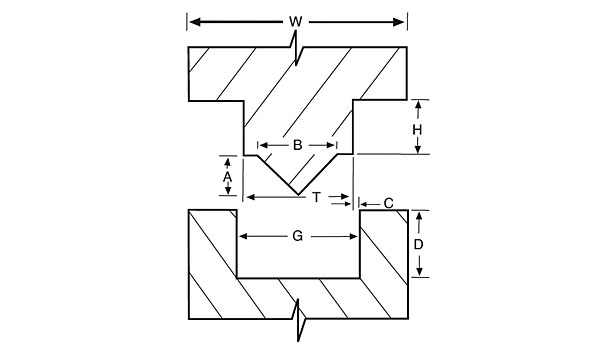

An energy director is a feature molded into the bottom of the top part. The energy director is triangular in section, with the point of the triangle providing the initial contact between the two parts. The energy director concentrates the vibrational energy in a small contact area.

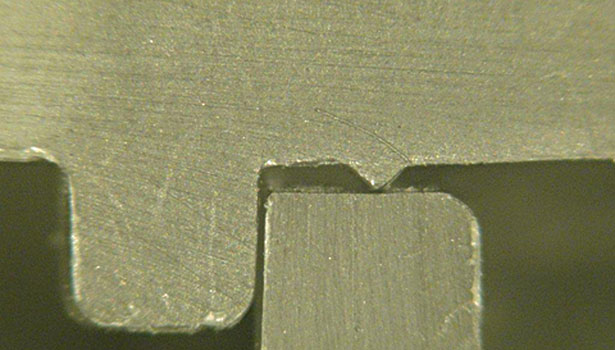

A shear joint provides strength and may be used to create a hermetic seal. The parts are designed to interfere initially in a small area. As ultrasonic vibrations are applied and the horn presses down on the parts, the top part melts its way into the bottom part. Many joint geometries are possible, but all use some way of providing a small initial contact area for the weld.

Developing an ultrasonically welded joint is not an exact science. Every part and every weld has its individual characteristics. Making the joint design and the welding process work together will require some iteration. First, determine what the joint needs to do and how you will measure its strength and functionality. You may want to perform pull and shear testing or pressurized leak testing, in addition to visual inspection of the weld.

After you have developed an initial joint geometry, make a set of prototype parts at the nominal dimensions and prepare, perhaps, two more sets with different fits (tighter or looser, for example), while keeping the other dimensions the same. One approach for a disk-shaped assembly of two parts that telescope together might be to use the same ID on the outer part and vary the OD on the inner part for a tighter or looser fit. Adjust the design and run further tests until you have a joint that welds well.

When you have achieved a joint design and weld process that work together, you can look forward to consistently clean, fast welds in your medical device assembly process.

Find a professional welding solution?

Click Altrasonic Welding to realize it !

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp