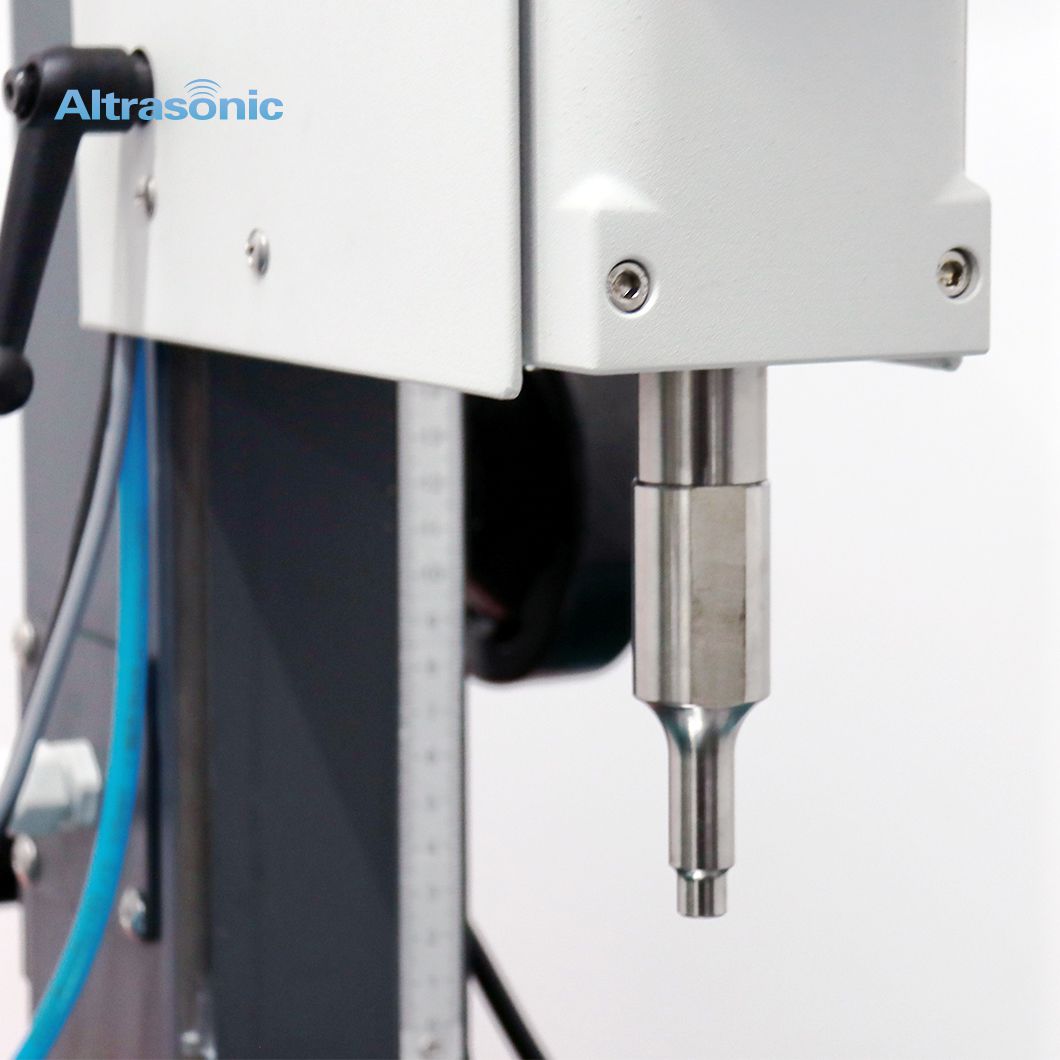

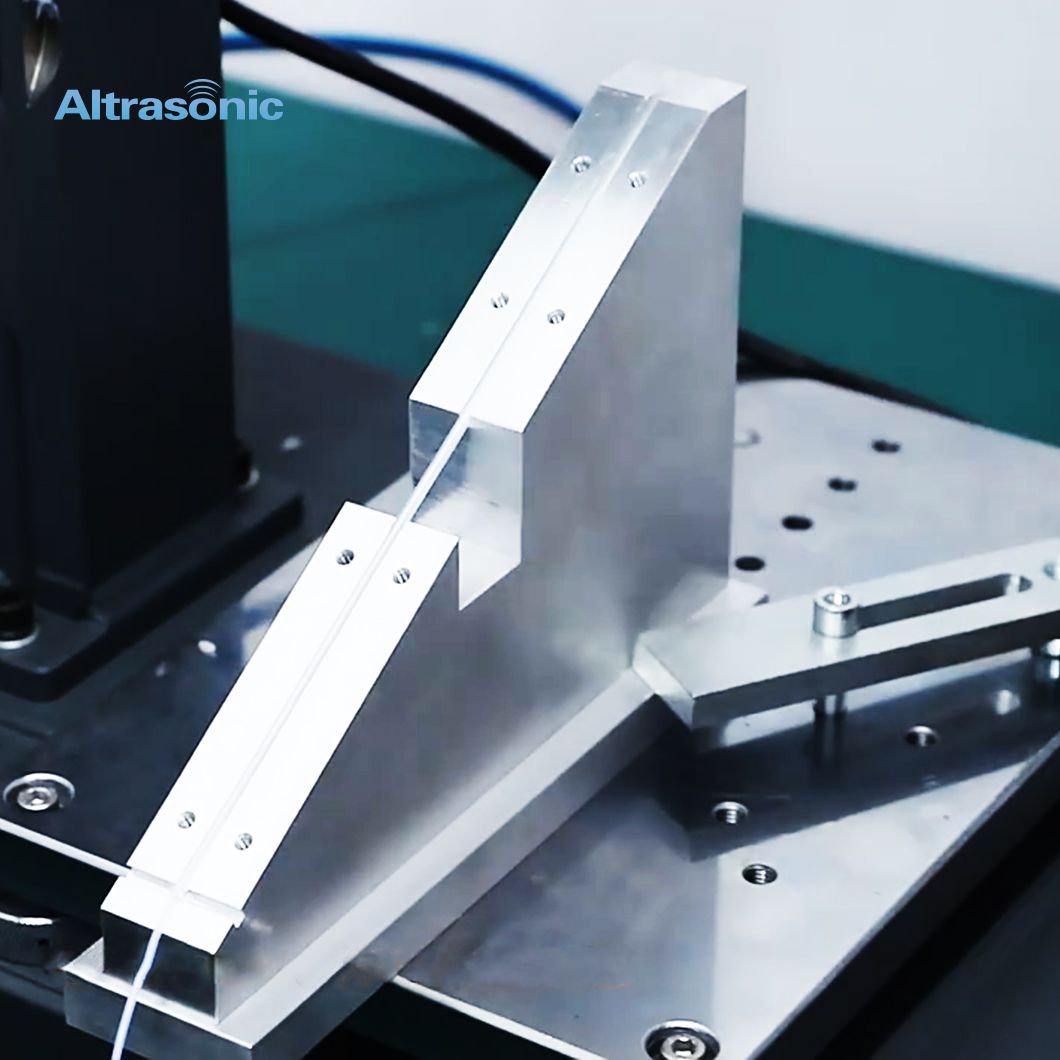

Compact and versatile, the C-Series ultrasonic welders are designed for small or mobile operations without compromising quality, making them the best choice for precision welding. This equipment is ideal for manufacturers who need a reliable, portable solution for rapid production.

Item No.:

HS-W30-C / HS-W35-C / HS-W40-CPayment:

T/T, West union, PaypalProduct origin:

ChinaGoods_stock:

9999Product weight:

50kgLead Time:

7

C-Series Precision Ultrasonic Welder for Plastic

(HS-W30-C / HS-W35-C / HS-W40-C)

At Altrasonic, we specialise in providing state-of-the-art ultrasonic welding technology to improve the efficiency and precision of your manufacturing processes. Our range of ultrasonic welding machines feature state-of-the-art designs that ensure high-quality, repeatable welding results for a wide range of materials and applications.

Features

Specification

| Item No | HS-W30-C |

HS-W35-C |

HS-W40-C |

| Frequency | 30kHz | 35kHz |

40kHz |

| Power | 1000W/1200W |

1000W/1200W |

1000W/1200W |

| Welding time | 0.01-9.99s |

0.01-9.99s |

0.01-9.99s |

| Air supply |

0.2-0.8MPa |

0.2-0.8MPa |

0.2-0.8MPa |

| Drive method | Cylinder drive |

Cylinder drive |

Cylinder drive |

| Welding stroke |

50-100mm |

50-100mm |

50-100mm |

| Weight | 50kg |

50kg |

50kg |

| Size (L*W*H) | 500*320*800mm |

500*320*800mm |

500*320*800mm |

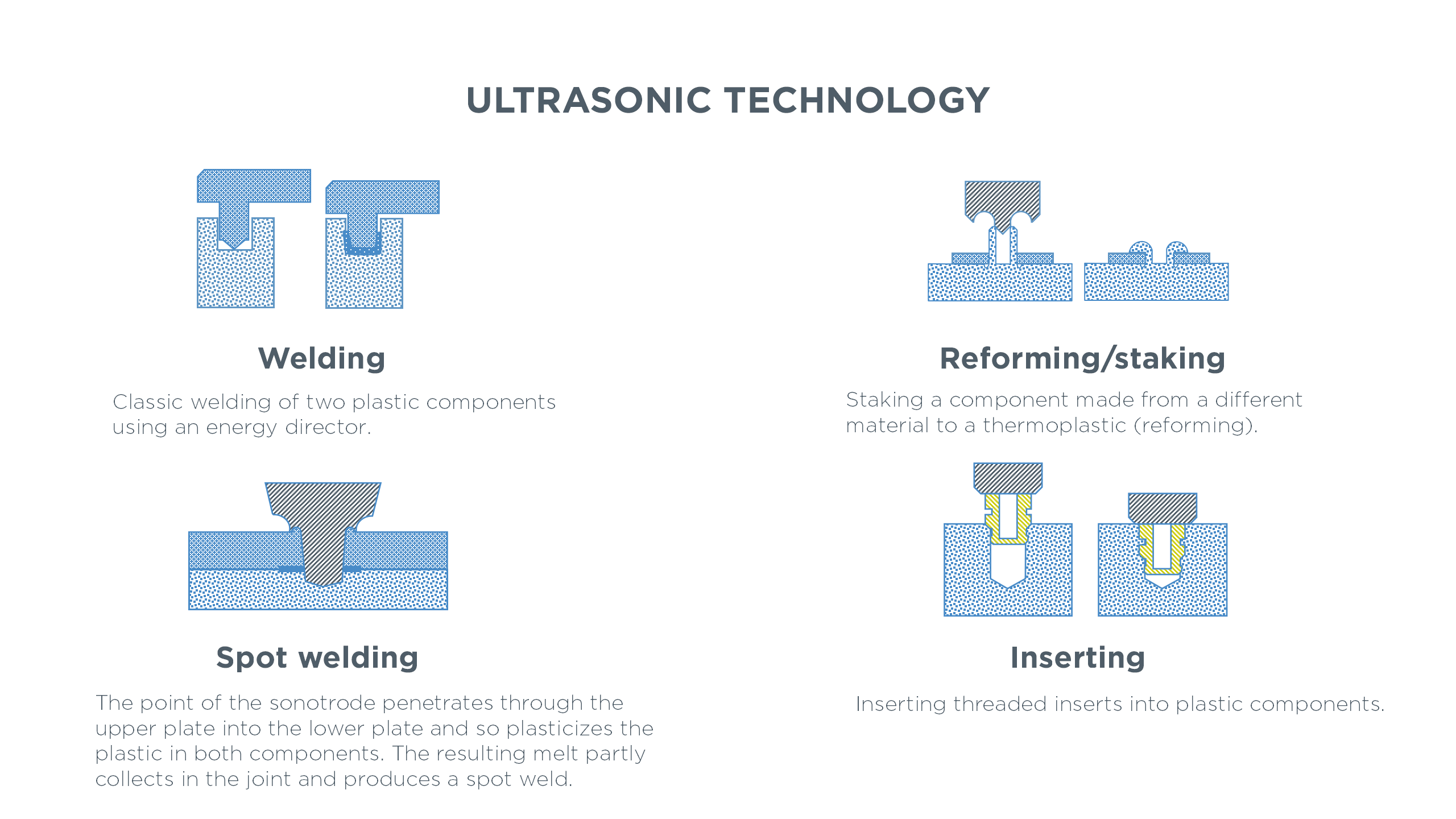

Working Principle

Ultrasonic welding machine is through the ultrasonic generator will current 220V, 50Hz or 110V, 60Hz electrical energy into 30kHz or 40kHz high-frequency electrical energy, and then through the transducer(converter) will be converted into high-frequency vibration of the electrical energy of the mechanical energy, through the weld head added to the plastic workpiece, through the surface of the workpiece and the intrinsic molecules of the friction of the interface to the interface of the temperature increases, when the temperature reaches the temperature of the workpiece itself. When the temperature reaches the temperature of the workpiece itself. When the temperature reaches the melting point of the workpiece itself, the interface of the workpiece melts rapidly and then fills the gap between the interfaces. When the vibration stops, the workpiece cools and moulds at the same time under the pressure of the welding head to achieve perfect welding.

Due to the limitations of the injection moulding process and other factors, in a considerable part of the complex shape of the plastic products can not be once injection moulding, which requires bonding, and along the many years of plastic bonding and thermal bonding process is quite backward, not only low efficiency, but also the existence of a certain degree of toxicity of the bonding agent, resulting in environmental pollution and labour protection and other issues.

The traditional process has been unable to apply the development needs of the modern plastics industry, so a novel plastics processing technology - ultrasonic plastic welding with its high efficiency, high quality, beautiful, energy-saving and other superiority stands out. Ultrasonic plastic welding machine in the welding of plastic products, that is, not filled with any adhesives, fillers or solvents, but also does not consume a lot of heat, with easy operation, fast welding speed, high welding strength, high productivity and other advantages. Therefore, ultrasonic welding technology is more and more widely used.

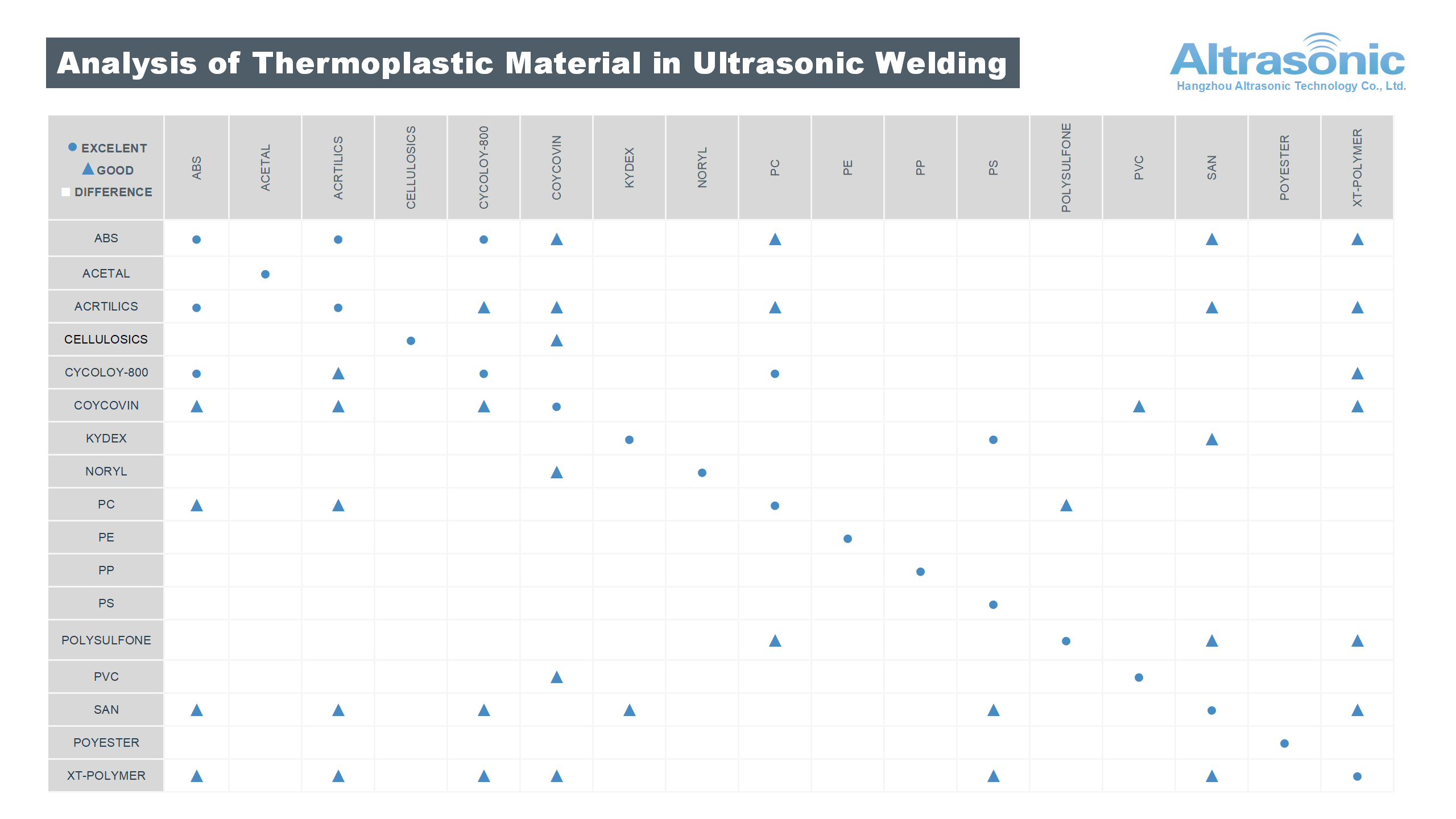

Ultrasonic welding is a high-tech thermoplastic products welding, a variety of thermoplastic parts can be ultrasonic welding processing, without the need to add solvents, adhesives or other ancillary products. The advantage is that it can exponentially increase productivity, reduce costs, improve product quality and safety.

Application

Ultrasonic plastic welder technology advanced prospects , contemporary society, a variety of plastic products, has penetrated into all areas of people's daily lives, but also widely used in aviation, ships, automobiles, electrical appliances, packaging, toys, electronics, textiles and other industries

Regular section: Steam iron, water dispenser plastic plate, TV set shell, transparent panel of the radio, shaker, portable fluorescent lamp cover, plastic frame of the juicer, vacuum cleaner parts, razor shell, TV set shell screws fixed seat, mosquito reduction lamp shell, washing machine dehydration tank, 3-inch floppy disk, USB connectors, calculator, electronic watch, cell phone shell, setter, switch and socket, pre-paid water meter meter, bluetooth earphone, injection molding parts vibration drop, toy pacifier, ball player card rating card box, photo albums, keychains, plastic lighters, toothpick cases, luggage, seat-sealed containers, hollow plate boxes, lipstick shells, cell phone chargers, power adapters, communication equipment nuts buried, consumables plastic parts, tape, toner cartridges, printer parts, fax machine parts, medical consumables, etc.

Automotive section: Welding of wheel arch cover, welding of headlamp lenses, wheelhouse or underfloor panelling, welding of supports, e.g. for parking sensors, headlamp washing system, side marker lamps or trailer couplings, welding of textile inserts, rear parcel shelves,,welding or riveting of instrument clusters, airbag covers or door panelling etc.

Product Details

Previous :

15-35kHz 1000-3600W B-Series Ultrasonic Plastic Welding MachineNext :

15kHz 3600W Plastic Ultrasonic Welder Ultrasonic Welding EquipmentIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp