Preparation and Development of Metal Powder by Ultrasonic Atomization

Preparation and Development of Metal Powder by Ultrasonic Atomization

Although conventional fine powder preparation methods such as high energy crushing, water atomization, gas atomization, and centrifugal atomization have entered large-scale industrial production stages, powder characteristics determined by the process methods such as particle size, particle size distribution, and powder Geometry and other aspects are difficult to meet the requirements of high-performance metal powder in some areas. In order to meet the needs of this new situation, people are constantly developing new metal powder ultrasonic atomization technology while developing and perfecting traditional metal powder preparation technology.

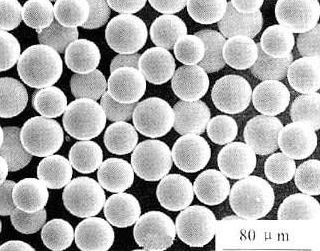

Metal powder morphology prepared by ultrasonic atomization

Sweden took the lead in the ultrasonic atomization to obtain metal powder. They used pulsed ultrasonic airflow generated by special nozzles to impact the metal flow, and successfully prepared aluminum alloy, copper alloy and other materials, which was later called ultrasonic aerosolization. Metal powder preparation technology, ultrasonic aerosolization is the use of ultrasonic vibration energy and airflow impact to break the liquid flow, the milling efficiency is significantly improved, but still need to consume a large amount of inert gas. Subsequently, the industry proposed the idea of directly atomizing liquid metal using high-frequency ultrasonic vibration. With the development of piezoelectric ceramic materials, transducer fabrication technology, ultrasonic power supply and signal tracking technology, metal ultrasonic vibration atomization technology has been applied in the field of medium and low melting point metal powder preparation. In recent years, the rapid development of power ultrasonic technology and the emergence of various new metal powder materials have promoted the continuous upgrading of metal ultrasonic atomization technology, from the initial development of only low melting point metals to the current attempts to use metals and alloys with different melting points. Powder preparation, ultrasonic atomization technology has undergone profound changes in process equipment and key technologies. The integration with traditional atomization technology is also a significant trend in the development of ultrasonic atomization technology. At present, a variety of composite high-efficiency atomization milling technology has emerged. Related metal ultrasonic atomization mechanism and key technology research of ultrasonic atomization have also caused domestic Wide attention outside.

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp