Principle of Ultrasonic Atomization to Prepare Metal Powder

Principle of Ultrasonic Atomization to Prepare Metal Powder

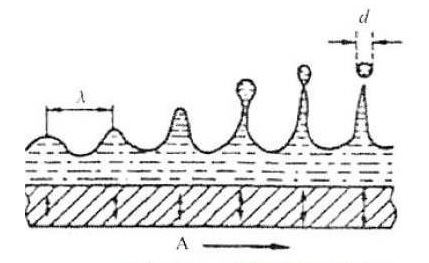

The basic principle of metal ultrasonic atomization is to use power source generator to convert power frequency alternating current into high frequency electromagnetic oscillation to provide ultrasonic transducer. The transducer converts high frequency electromagnetic oscillation into weak by means of the stretching effect of piezoelectric crystal. Mechanical vibration, the ultrasonic concentrator then magnifies and transmits the particle displacement or velocity of the mechanical vibration to the ultrasonic tool head. When the molten metal flows from the liquid guiding tube to the surface of the ultrasonic tool head, it is spread into a liquid film under the action of ultrasonic vibration. When the amplitude of the vibration surface reaches a certain value, the thin liquid layer is crushed by the ultrasonic vibration. The evoked droplets fly out of the vibrating surface to form droplets.

In the actual atomization process, when the ultrasonic intensity exceeds the cavitation field value of the liquid, a strong cavitation effect is generated in the liquid medium on the vibrating surface, and a large number of bubbles caused by the cavitation effect continuously grow and collapse during the vibration process. The periodic surface tension wave law causes aperiodic disturbances. If the cavitation effect is considered, the atomization mechanism will be more complicated. At present, there are still two different views on the interpretation of the ultrasonic atomization mechanism. The compromised view is that the ultrasonic cavitation and the tension wave effect work together. The theory holds that ultrasonic vibration atomization is dominated by droplets formed by tension wave excitation, and acoustic cavitation acts as a random phenomenon, which constitutes interference with periodic surface tension waves, and randomly generates droplets of different particle sizes.

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp