Our 20kHz ultrasonic welding equipment offers you maximum flexibility to take advantage of the ultrasonic frequency most commonly used in plastics assembly. 20kHz is the industry standard for a wide range of applications and thermoplastic parts.

Item No.:

HS-W2030-BPayment:

T/T, West union, PaypalProduct origin:

ChinaGoods_stock:

9999Product weight:

85kgLead Time:

7

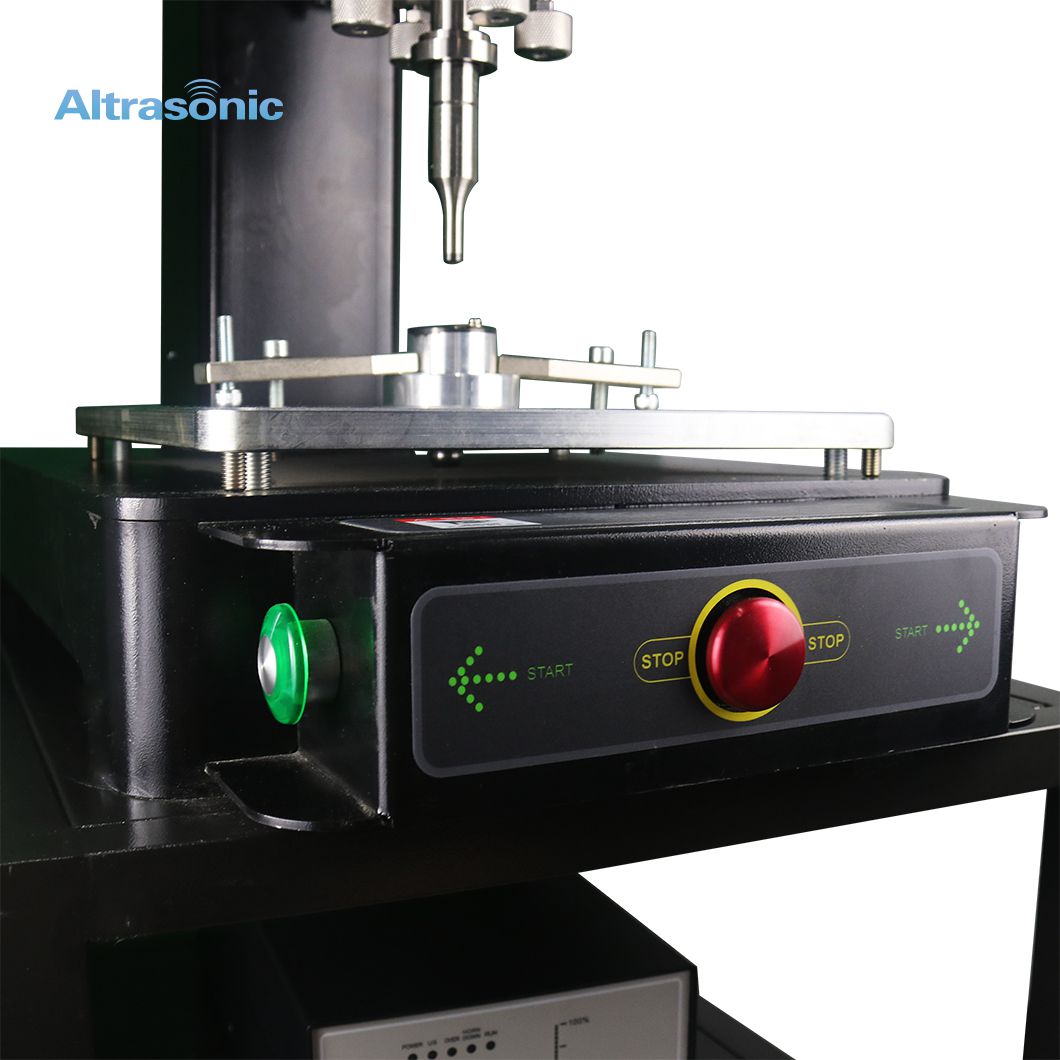

20kHz 3000W Ultrasonic Welder for Plastic Welding

FEATURES

Specification:

| Item No | HS-W2030-B |

| Frequency | 20kHz |

| Power | 3000W |

| Welding time | 0.01-9.99s |

| Air supply |

0.3-1MPa |

| Drive method | Cylinder drive |

| Welding stroke |

75-125mm |

| Weight | 85kg |

| Size (L*W*H) | 580*420*1200mm |

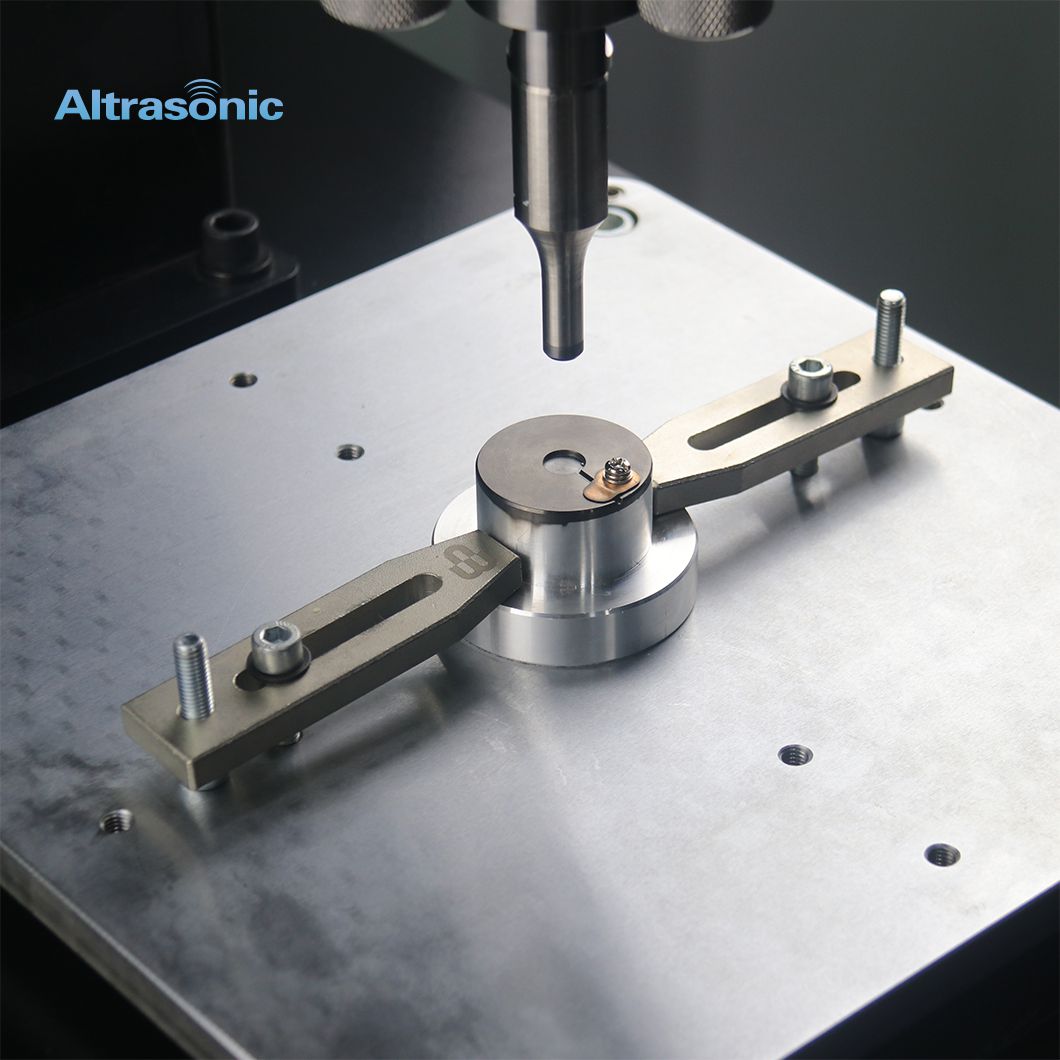

Working Principle:

The principle of ultrasonic welding machine is generated by the generator 20kHz high-voltage, high-frequency signal, through the transducer system, the signal is converted into high-frequency mechanical vibration, added to the plastic workpiece, through the surface of the workpiece and in the friction between the molecules and the interface to the interface to the temperature rise, when the temperature reaches the melting point of the workpiece itself, so that the interface of the workpiece quickly melted, and then fill the gap between the interface, when the vibration stops! When the vibration stops, the workpiece is cooled and shaped under a certain pressure, and the purpose of welding is achieved. When the vibration stops, the workpiece is cooled and shaped under a certain pressure at the same time, then the purpose of welding is achieved. The ultrasonic welding machine transmits ultrasonic energy to the welding zone through the upper part of the weldment. Due to the high acoustic impedance of the welding zone (i.e. the interface between the two welds), a localised high temperature is generated. And because of the poor thermal conductivity of plastic, a moment can not be distributed in a timely manner, gathered in the weld area, resulting in contact with the surface of the two plastics rapidly melted, coupled with a certain amount of pressure, so that it fused into one. When the ultrasonic stop acting, so that the pressure continues, there is a little insulation time, so that the solidification of the shape, thus forming a solid molecular chain, to achieve the purpose of welding, welding strength can be close to the strength of the raw material body.

Application:

Conventional parts: steam iron, water dispenser plastic plate, TV shell, radio transparent panel, vibrator, lampshade, juicer plastic frame, hoover parts, razor shell, TV shell, mosquito light shell, washing machine dehydration box, 3-inch floppy discs, USB connector, calculator, electronic watch, mobile phone shell, setter, switch socket, water meter meter, bluetooth headset, injection moulded parts vibration drop, Toy pacifier, ball player card rating card box, photo albums, keychains, plastic lighters, toothpick boxes, luggage, seat sealing containers, hollow plate boxes, lipstick shells, mobile phone chargers, power adapters, communication equipment nut pre-built parts, consumables plastic parts, adhesive tapes, toner cartridges, printer parts, fax machine parts, medical consumables and so on.

Automotive parts: Welding of wheel arches, welding of headlight lenses, welding of wheel chambers or underfloor panelling, welding of brackets (e.g. parking sensors, headlight cleaning systems, side marker lights or trailer couplings), welding of textile inserts, welding of rear luggage racks, welding or riveting of dashboards, airbag covers or door panels.

Previous :

15kHz 2600W Ultrasonic Welding Plastic MachineNext :

20kHz 2000W Ultrasonic Plastic Welding MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp