Ultrasonic drilling machine: Ultrasonic drilling is a method that uses the ultrasonic vibration of the end face of the drill bit to drill the glass through the abrasive suspension.

Item No.:

HS-M20-WPayment:

T/T, PayPal, Western UnionProduct origin:

ChinaColor:

Silver and GreenShipping port:

Shanghai or NingboLead Time:

45

20Khz Ultrasonic Machining Assisted for ceramic quartz silicon Jewelry Ferrite driller milling machine/BT30 /BT40 /BT50 /HSK63

Specification:

Item No

HS-M20

Frequency

20 kHz

Power

500 watt

Spindle taper

BT30

Rotation speed

Maximum 24,000 r/min

Amplitude

1~10 um

Tool interface model

ER-16

Weight

30 KG

Generator

Digital

Description:

Ultrasonic grinding processing technology: Ultrasonic grinding is a process method that uses the forced vibration of the grinding wheel (or workpiece) to perform grinding during the grinding process. When the magnetization power supply of the ultrasonic generator is started, a certain ultrasonic frequency current and a DC current for magnetization are supplied to the nickel magnetostrictive transducer, and an alternating ultrasonic frequency magnetic field and a constant polarizing magnetic field are generated in the transducer coil. The transducer generates longitudinal mechanical vibration energy of the same frequency, which is transmitted to the horn at the same time, and the amplitude is amplified to a predetermined value, and the resonant cutter bar is driven to perform vibration cutting. The transducer, horn, and cutter rod are in resonance with the ultrasonic frequency output by the generator, forming a resonant system, and their solids should be at the displacement node. At the same time, the cutting length of each abrasive particle is shortened, and the abrasive dust becomes finer and shorter. In addition, the abrasive dust is not easy to block the grinding wheel. The abrasive particle can maintain a sharp state. Generally, it can reduce the grinding force by 30% to 60% compared with ordinary grinding. Cutting temperature increases the processing efficiency by 1~4 times. In addition, ultrasonic vibration grinding also has the advantages of compact structure, low cost, and easy promotion and application. Ultrasonic grinding equipment cleaning equipment with heating system is strictly prohibited to turn on the heating switch when there is no liquid.

Advantages:

1. Suitable for processing hard metals, stones, diamonds, with high precision

2. Can be installed on CNC machine tools, can be used with a variety of spindle tool holders

3. Diversified tool sizes, the tool head can also be customized according to actual needs

Workshop:

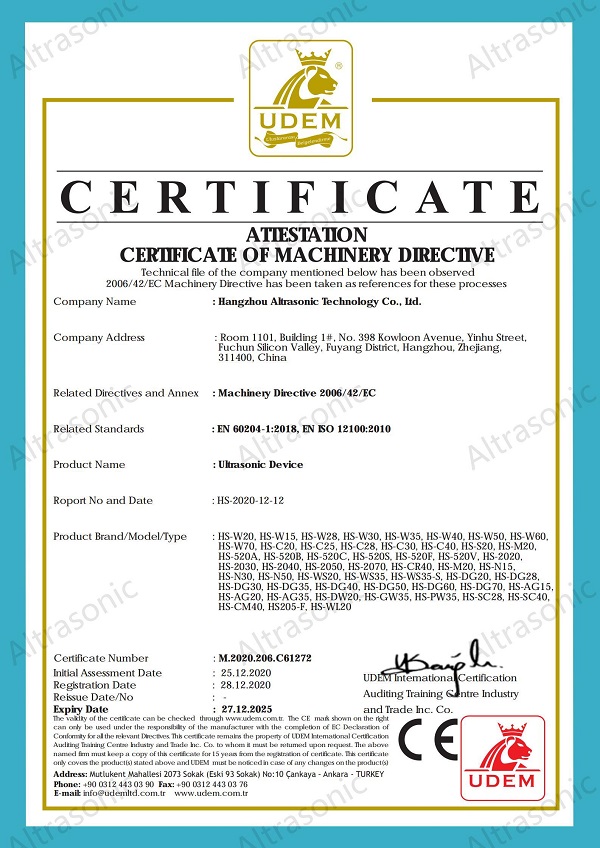

CE:

Shipping:

Payment:

Previous :

High-tech non-contact Ultrasonic Milling 20khz 30000 rpm Metal Assisted MachiningNext :

High Speed Metal Abrasive Finishing Rotary Milling Cutter for Diamond ProcessingIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp