Item No.:

HS-M20-WPayment:

T/T, PayPal, Western UnionProduct origin:

ChinaColor:

Silver and GreenShipping port:

Shanghai or NingboLead Time:

15Specification

Item No.

HS-M20-W

Voltage

220V/110V

Rotation speed

Max. 24,000 r/min

Spindle taper

BT40

Frequnecy

20kHZ

Power

500 watt

Generator

Digital Type

Application

Milling Machining

Certificate

CE

Feature

High Temperature Resist

Pictures

About Us

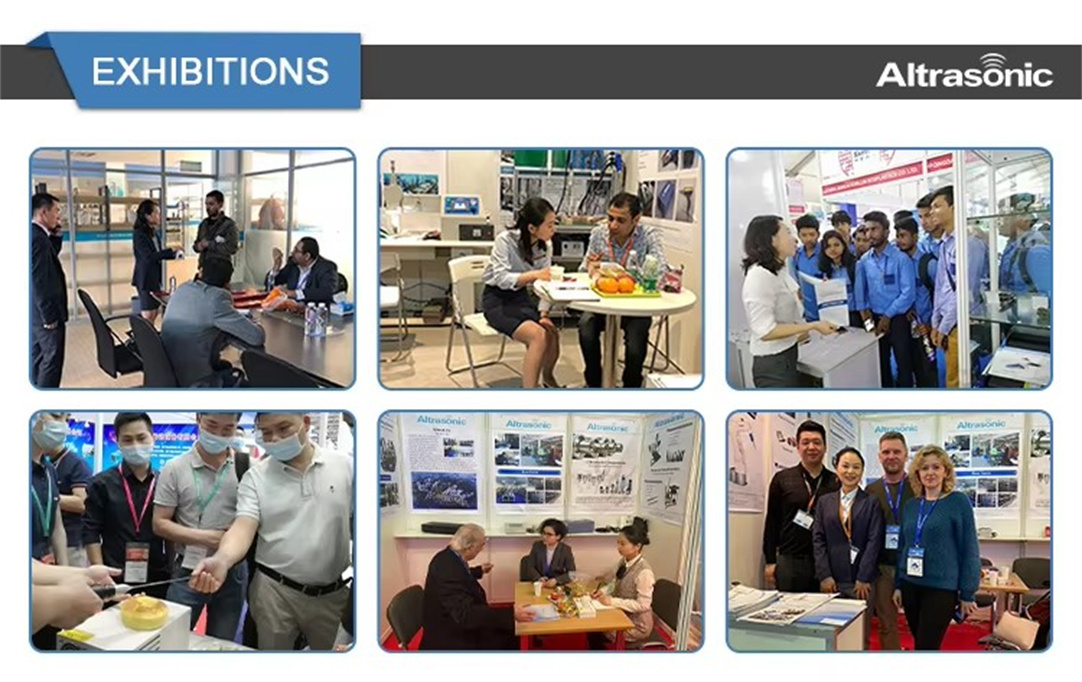

Hangzhou Altrasonic Technology Co., Ltd.is a leading company specializing in ultrasonic technology solutions. We have established ourselves as a trusted manufacturer and supplier of ultrasonic cutting machines, ultrasonic sewing machines, welding machines, and components.

At Altrasonic, we are committed to providing innovative and high-quality products to meet the diverse requirements of our customers. Our ultrasonic solutions are widely used in industries such as automotive, food processing, medical, clothing fabric processing, packaging, and more.

With a team of highly skilled professionals and engineers, we strive to deliver cutting-edge technology and exceptional customer service. We take pride in our state-of-the-art manufacturing facilities equipped with imported CNC machining centers to ensure precisionand efficiency in our production processes.

As a company dedicated to continuous improvement and innovation, we have obtainednumerous technical patents and certifications including lS09001 quality management system certification and CE certificate. These achievements reflect our commitment to delivering reliable and superior products that meet international standards

At Altrasonic, we value the importance of customer satisfaction. Our dedicated team is available 24/7 to provide prompt assistance and support to our valued customers worldwide. We believe in building long-term partnerships based on trust, reliability, and mutual success.

Thank you for considering ALTRASONIC as your trusted partner for ultrasonic technology solutions. We look forward to serving you with our expertise and providing you with the most effective ultrasonic solutions for your specific requirements.

Our Brand Story

The founder of Altrasonic knew that a unique and meaningful brand was crucial to the

company's influence and recognition. When designing the company's LOGO, she was inspired

by the English word ultrasonic. Change the "U" to "A" to become "ALTRASONIC", which

happens to mean ultrasonic. Altrasonic is not only the name of the company, but also a tribute

and commitment to ultrasonic technology, reflecting the company's pursuit of technological

innovation and professionalism.

In terms of brand positioning, Altrasonic is not only a corporate name, but also a commitment

and mission. They hope that with the company's continuous promotion of the brand, when

customers at home and abroad search for ultrasonic on Google, they will naturally equate

Altrasonic with ultrasonic. When looking for ultrasonic, they will search for Altrasonic. This will

be deeply implanted in the minds of customers. The important thing is The brand

ALTRASONIC is not from the United States, Germany, or Switzerland, but a brand from China, purely made in China. Altrasonic is not only a company, but also a collection of sentimental and warm-hearted people. They hope that through the influence of the brand, the lovely, warm, dreamy and sentimental

Altrasonic people behind the brand can be seen by the world. . Altrasonic hopes to contribute to the advancement of ultrasonic technology in China through

its unremitting efforts.Become a leader and benchmark in the field of ultrasonic and let the

world see the power of Chinese science and technology and the spark of dreams. Altrasonic,

the future light of ultrasonic, warms every corner of the world.

FAQ

Q: Do you have it in stock?

A: Most of product available, if you have special requirement, pls feel free contact us, all issue can be solved through communication.

Q: Could you advise to us the design based on our special requirements or based on our object samples?

A: Of course, Our mission is make your idea show in the products itself.

Q: How long do you make the order product?

A: Our main mark is fast shipment, usually 3-7days after all details confirmed.

Q: . Do you have operating manual?

A: Of course, we will put it with the goods together.Also we will upload video in YouTube and inform you the related link.

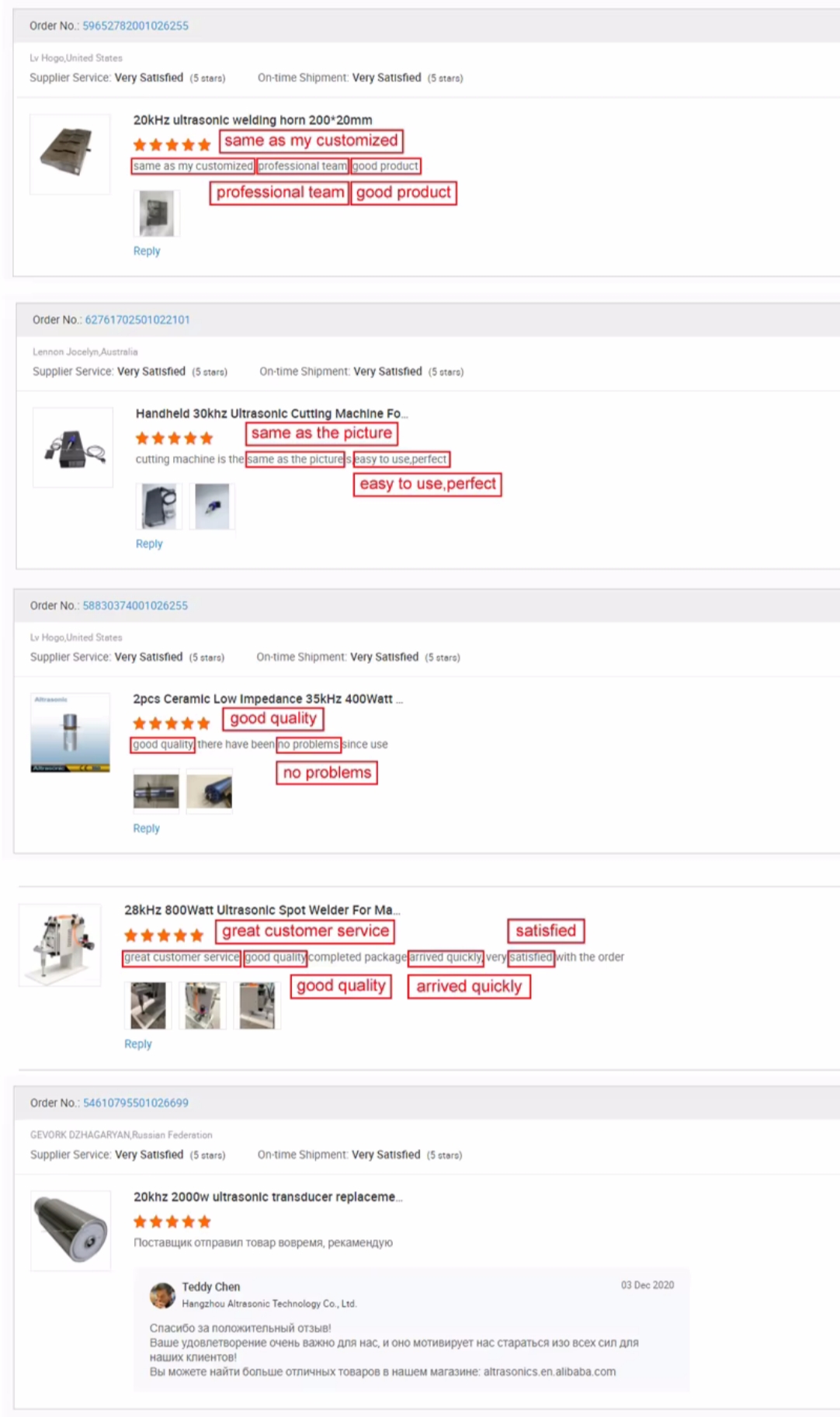

Q: How about the quality?

A: We have export to many other customers from all over the world,the feed back is good,quality is the first for our factory, our main markets is USA and European etc

Q: Could you do OEM?

A: Yes, of course.Everybody like OEM,We cherish the OEM VIP buyer like you,We can produce according customers’ requirement,just send us your requirements and design of drawing and sample

Q: Could we as your agent?

A: Of course.We are looking for sole agent in some Country who have the willing to cooperate with us for long business term.

Q: Terms of Payment

A: We have flexible and active payment if order huge.

Q: What custom requirements can you accept?

A: LOGO, product appearance, tool head size, packaging requirements, special customized requirements will be accepted, etc.

Previous :

HS-M20-DH Ultrasonic Machining Center CNC Milling Drilling Machine Tool HeadNext :

M20 Ultrasonic Machining For Zirconia Chrome Titanium MaterialIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp