Ultrasonic vibration cutting is a kind of pulse cutting from a microscopic point of view.

Item No.:

HS-M20-WPayment:

T/T, PayPal, Western UnionProduct origin:

ChinaColor:

Silver and GreenShipping port:

Shanghai or NingboLead Time:

45

Ultrasonic fine processing milling and turning equipment hard and brittle material processing

Specification:

Item No

HS-M20

Frequency

20 kHz

Power

500 watt

Spindle taper

BT30

Rotation speed

Maximum 24,000 r/min

Amplitude

1~10 um

Tool interface model

ER-16

Weight

30 KG

Generator

Digital

Description:

Ultrasonic vibration cutting is a kind of pulse cutting from a microscopic point of view. In a vibration cycle, the effective cutting time is very short, and it is completely separated from the workpiece and the chips for more than 80% of the time. The intermittent contact with the workpiece and the chips reduces the friction, the heat generated is greatly reduced, and the cutting force is significantly reduced, which avoids the "knife" phenomenon in ordinary cutting and does not produce built-up edge. Using this kind of vibration cutting, precision machining can be carried out on ordinary machine tools. The geometric tolerances such as roundness, cylindricity, flatness, parallelism, and straightness mainly depend on the accuracy of the machine tool spindle and guide rail, and can reach close to zero error. It is possible to replace grinding by car, reaming by drilling, and grinding by milling. Compared with high-speed hard cutting, it does not require high machine tool rigidity and does not damage the surface metallographic structure of the workpiece. In the finishing machining of curved contour parts, the profiling machining can be carried out with the help of CNC lathes, machining centers, etc., which can save the expensive purchase cost of CNC grinders.

Brief introduction of the performance of the ultrasonic milling device:

1 The cutting force is small, about 1/3-1/10 of the ordinary cutting force.

2 The machining accuracy is high, which mainly depends on the accuracy of the machine tool used, and the shape and position tolerance of the processed workpiece can almost be close to the relevant accuracy of the machine tool.

3 The cutting temperature is low, and the workpiece is kept at room temperature.

4 There is no built-up edge, small deformation of the workpiece, and no burrs.

Advantages:

1. Easy to process and polish tiny holes. Compared with the ordinary processing method of micro-holes, it is not easy to remove chips, the tool strength is low, and the ultrasonic processing frequency is high. It can remove the material at a frequency of more than 20,000 times per second, reduce the cutting force of the tool, reduce the damage of the tool, ensure the processing efficiency, and improve the processing. Surface Quality.

2. No need to change the machine structure. With the continuous development of ultrasonic processing technology, a professional ultrasonic milling equipment manufacturer in Beijing, the current ultrasonic system can achieve miniaturization and modular design, suitable for different types of processing machine tools, low barriers to use, and rapid deployment.

3. It can be combined with other processing methods to form compound processing. It can be combined with electric discharge machining, electrochemical machining, cutting machining, ultrasonic milling equipment manufacturers, grinding machining, etc. to form composite machining.

Workshop:

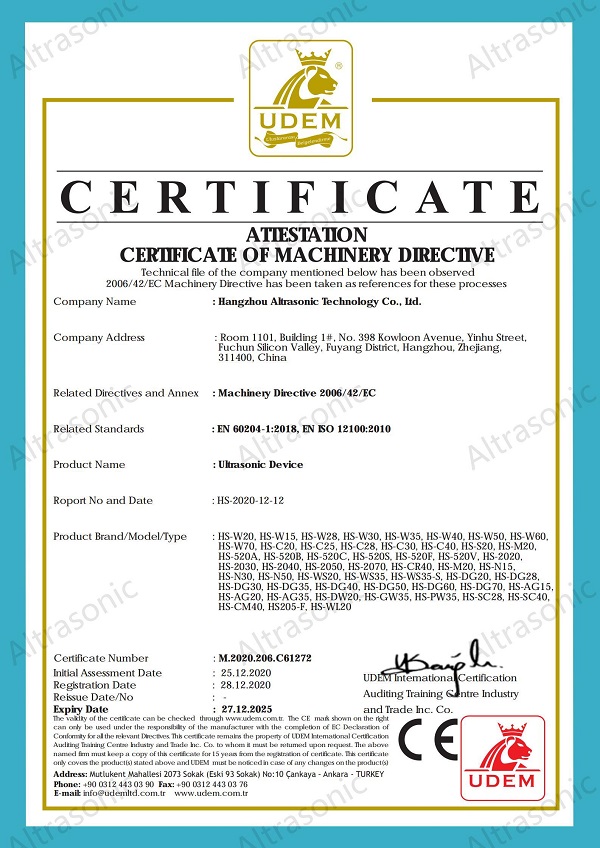

CE:

Shipping:

Payment:

Previous :

Electromagnetic transmission type high-speed ultrasonic milling machine Ultrasonic drilling machineNext :

Ultrasonic milling equipment installed on CNC machine tools Spindle taper BT 30 BT40 BT50 HSK63 CT40If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp