The latest processing technology installed on CNC machine tools adds ultrasound to traditional milling.

Item No.:

HS-M20Payment:

T/T, PayPal, Western UnionProduct origin:

ChinaColor:

Silver and GreenShipping port:

Shanghai or NingboLead Time:

45

20K Ultrasonic finishing Machining Process Mounted On CNC Machine ultrasonic turning drilling milling machine

Specification:

Item No.: HS-M20

Frequency: 20kHz

Power: 500Watt

Speed: 20,000RPM

Amplitude: 10um or more

Diameter of Horn:

Milling: Φ1-Ф13mm

Drilling:Ф2-Ф6mm

Spindle: BT40 / BT50 / R8 / HSK63 / ISO / CAT

(Special spindles are made per request.)

Description:

In the ultrasonic milling process, the tool rotates while vibrating with the ultrasonic high frequency. At the same time, under the control of the CNC system, each layer does the feed movement in the X and Y directions. Under the combined action of the three movements of the tool, the abrasive particles continuously hammer, impact, polish and scrape the surface of the hard and brittle material. When the tool, abrasive particles and the workpiece are not in contact, the removal of material is mainly due to the impact of abrasive particles, and the effect of tool rotation is relatively weak: when the three contact, the abrasive particles directly act on the surface of the workpiece. During the process, part of the abrasive particles are pressed into the tool due to the pressure of the tool, and the exposed part scribes the surface of the workpiece. Under the action of the tool rotation, it traverses a circular track and forms an arc-shaped dent on the surface of the workpiece. . The other part of the abrasive particles rolls between the workpiece and the tool, producing a rolling effect, causing micro-cracks on the surface of the workpiece. After the cracks propagate, the surface of the workpiece is brittle and collapsed to form chips.

The function of various parts are described below:

1. Transducer: The transducer mainly consists of a cylinder which is made up of piezoelectric ceramic. It converts electrical energy into mechanical vibration. Transducer then vibrates sonotrode at low amplitude and high frequency.

2. Sonotrode: It is made of low carbon steel. One end of it is connected with the transducer and other end contains tool. The sonotrode vibrates at low amplitude and high frequency and removes material from the w/p by abrasion where it contacts it.

3. Generator: The generator consists of an electronic oscillator which produces an alternating current at high frequency. The frequency produced is usually in 20kHz in ultrasonic range.

Workshop:

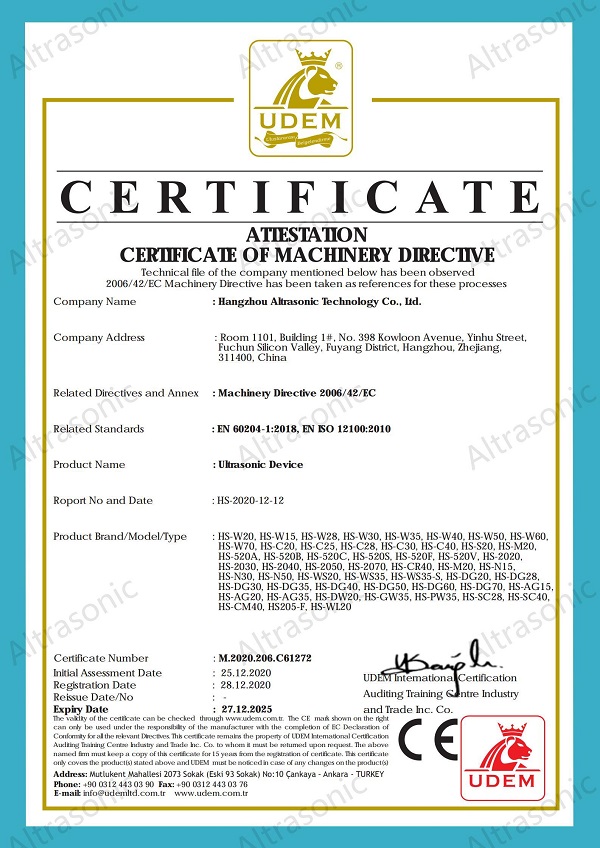

CE:

Shipping:

Payment:

Previous :

Auxiliary processing Rotary Ultrasonic Vibration Machining for Opal productsNext :

Stable Amplitude Ultrasonic milling machine of BT30/40/50 HSK63A CT40If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp