The ultrasonic agitator includes a shell, a mixing barrel, and an ultrasonic generating mechanism. The ultrasonic generating mechanism is equipped with an ultrasonic vibrator. The stirring device of the telescopic device, the stirring device makes the stirring wheel in the rotating state reciprocate up and down in the stirring barrel to mix the raw materials uniformly. The utility model enables th...

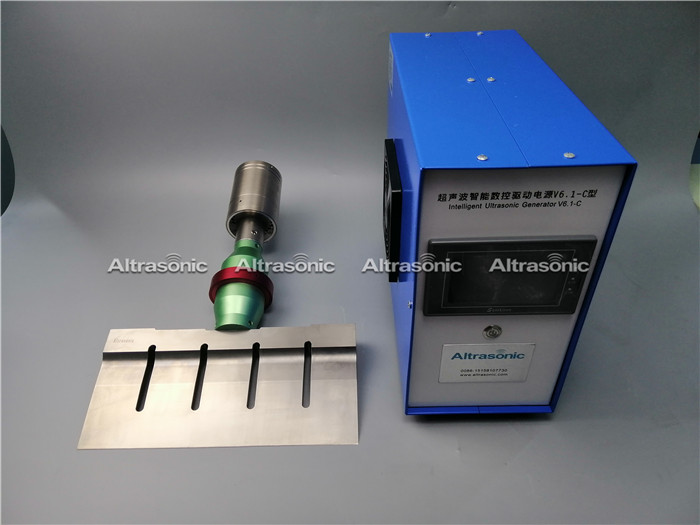

Ultrasonic cutting is a kind of ultrasonic equipment specially used for cutting, and it is one of the important categories of ultrasonic applications. Ultrasonic cutting, through the action of ultrasonic waves, causes the grinding wheel blade to generate instantaneous telescopic vibration in the radial direction, which can cause repeated collisions between abrasive grains and processed objects und...

The transducer of the ultrasonic welding machine vibrates at the resonant frequency without a load, which can be approximated as a pure resistance. However, once working with a load, due to the change of the load, the equivalent circuit parameters of the transducer will change, and the actual working frequency is different from the resonant frequency of the power supply. At this time, the welding ...

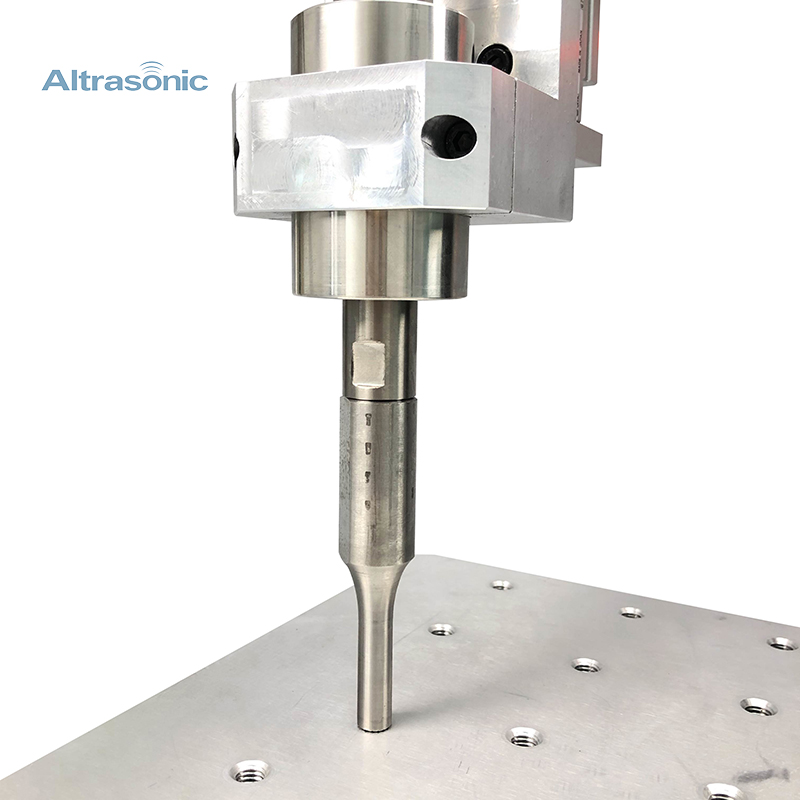

1. Welding method: Ultrasonic vibration transmits the ultrasonic wave to the weldment along with the welding head. Due to the large acoustic resistance at the two weldments, local high temperature is generated and the interface of the weldment is melted. Under a certain pressure, the two weldments can achieve a beautiful, fast and firm welding effect. 2. Forming method: The plastic workpiec...

In ultrasonic work, the product and the mold surface can get the proper welding effect as long as the contact is accurate. In fact, this is only a superficial view. Since the ultrasonic wave is frictional vibration, it will produce the phenomenon of sound wave transmission. If we only observe the degree of stability of the hardware (mold fixture), and ignore the integra...

What are the requirements and effects of ultrasonic welding on materials The effect of ultrasonic welding is directly proportional to the modulus of elasticity, coefficient of friction, and thermal conductivity, and inversely proportional to its density, specific heat capacity, and melting point. The effect of ultrasonic welding is mainly related to the melting point of the material a...

Whenever the ultrasonic wave acts on the thermoplastic plastic contact surface, it will produce tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area through the upper weldment. The acoustic resistance at the interface of the two welds is large, so local h...

1. Pretreatment of common faults of ultrasonic metal welding machine 1. Test the voltage of each power supply in the ultrasonic generator to check whether it is normal and the relevant signals of the controller board and output board. 2. Check whether the short-circuit or idling protection circuit is active and there are no shortcomings. 3. Check whether the temperature of the power supply exceeds...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp