Ultrasonic cutting uses ultrasonic energy to locally heat and melt the material to be cut to achieve the purpose of cutting, so there is no need for a sharp edge. Especially suitable for cutting viscous and elastic materials, frozen materials (such as food, rubber, etc.) or objects that are inconvenient to pressurize. working principle: The principle of ultrasonic cutting is completely different f...

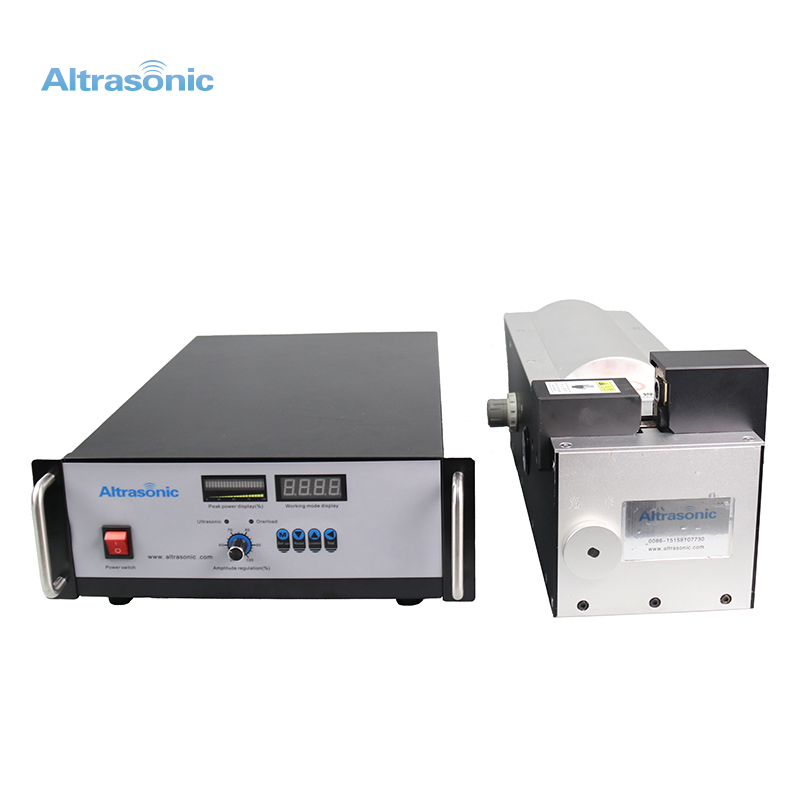

Using ultrasonic welding technology, the high-frequency electric energy is converted into mechanical vibration energy through the ultrasonic transducer, and then the mechanical vibration energy is transferred to the welding head after changing the amplitude through the banner device. When the welding head is close to the surface of the processed product, ultrasonic waves are automatically generate...

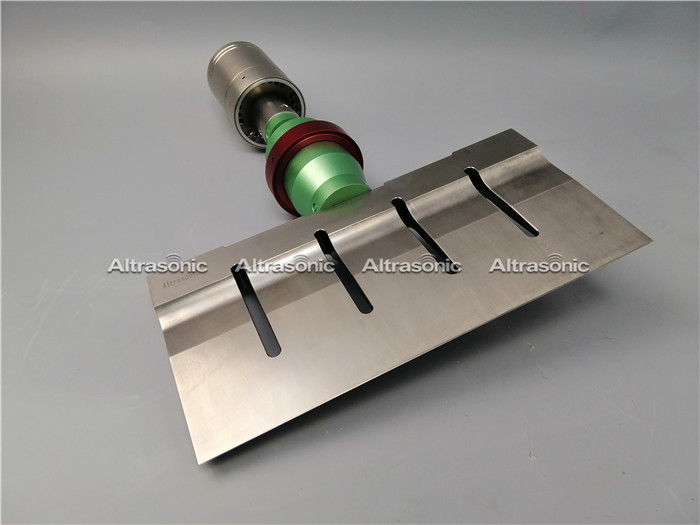

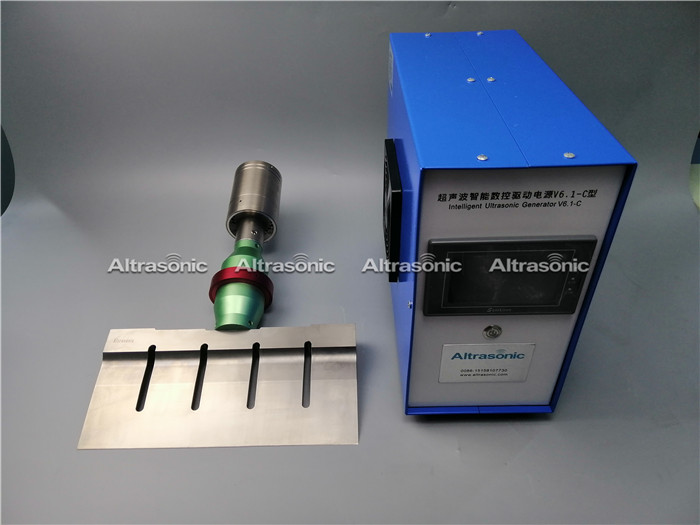

Ultrasonic cutting is a kind of ultrasonic equipment specially used for cutting, and it is one of the important categories of ultrasonic applications. Ultrasonic cutting, through the action of ultrasonic waves, causes the grinding wheel blade to generate instantaneous telescopic vibration in the radial direction, which can cause repeated collisions between abrasive grains and processed objects und...

Ultrasonic harness welding machine is a mechanical process, no current flows through the workpiece, so the conductivity of the metal has no effect. Contaminants and oxide layers are generally attached to the metal surface. Using an ultrasonic wire beam welding machine, there is no need to pre-treat the metal surface. Ultrasonic vibration can directly shake the attachment and remove it. Another imp...

Ultrasonic molds are used in conjunction with ultrasonic welding machines. The purpose is to weld products such as plastics and metals. Different welding objects require different tool heads. Whether it is near-field welding or transmission welding, only half-wavelength tool heads can make the welding end surface reach The amplitude. 1. The design of ultrasonic mould is not reasonable enough and t...

15KHZ ultrasonic molds and 20KHZ ultrasonic molds are all made of imported aluminum-magnesium alloy 7075. The frequency is good, the hardness is high, and it is durable! The design and production of ultrasonic molds are very important. You may often have this idea: The design and production of ultrasonic molds must be very simple. Do not be misled. When using an improperly processed or untuned wel...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp