The ultrasonic frequency emitted by the ultrasonic welding machine is higher than 20000 Hz. It is a sound wave with good directionality and greater energy. It can be used not only for welding, but also for distance measurement, cleaning and speed measurement. When ultrasonic waves act on the surface of a welded object, it can produce tens of thousands of high-frequency vibrations per second in a s...

Ultrasonic molds are used in conjunction with ultrasonic welding machines. The purpose is to weld plastic and metal products. Different welding objects require different tool heads. Whether it is near-field welding or transmission welding, only half-wavelength tool heads can make the welding end surface reach Amplitude of. 1. Ultrasonic mold design is not reasonable enough, and the production is n...

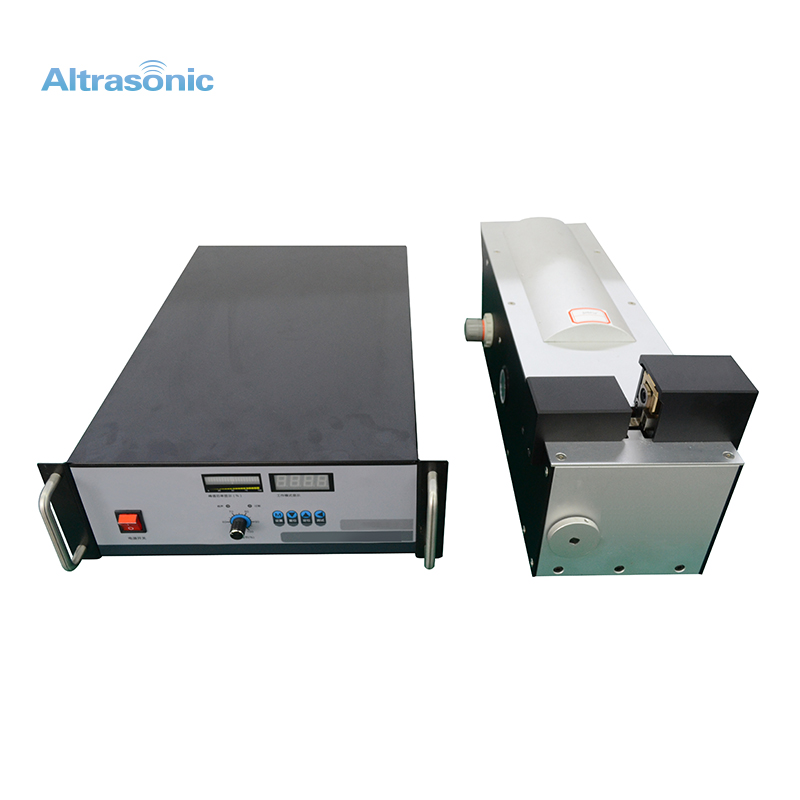

Ultrasonic harness welding machine is a mechanical process, no current flows through the workpiece, so the conductivity of the metal has no effect. Contaminants and oxide layers are generally attached to the metal surface. Using an ultrasonic wire beam welding machine, there is no need to pre-treat the metal surface. Ultrasonic vibration can directly shake the attachment and remove it. Another imp...

Why is heat treatment necessary when operating ultrasonic molds? Ultrasonic molds are often heat-treated during the production process. Most of the steel molds that are usually made are made of coiled steel. If there is no hardness, it will not be punched several times, and the edge of the mold will be blunt, and it will not be able to punch. The mold is also easily deformed. The molds made with a...

Precautions and maintenance methods for ultrasonic plastic welding machine 1. The equipment circuit must be reliably grounded to protect personal safety 2. The welding head, bottom mold and worktable should be kept clean 3. The welding head drops and the welding speed is not too fast 4. Take good care of the machine and strictly prohibit brutal operation 5. It is forbidden to use steel tools to to...

In the ultrasonic plastic welding operation, it is common phenomenon that the surface of the plastic product is scarred, the joint is broken, and the crack is cracked. Because there will be two situations in the ultrasonic plastic welding operation: 1. The high heat energy will directly contact the surface of the plastic product. 2. There...

The welding effect is good or bad, there are 3 major factors: 1. The material of the plastic part; 2. The welding line design of the plastic part; 3. The structure design of the plastic part. At the beginning of the injection of plastic parts, we have to think about these three elements, otherwise no matter how good ultrasonic equipment is used to weld, the effect will not meet the id...

Ultrasonic mold design is a very complex task, which needs to be considered comprehensively according to the mold material, size, machine frequency, and acoustic principles. Simply put, the purpose of ultrasonic mold grooving is to destroy the transverse waves generated in ultrasonic transmission. Generally, the grooving is at 1/2 the wavelength of the transverse wave, which is mainly considered b...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp