spot welding A. There is no need to design the welding wire in advance to achieve the purpose of welding. B. For relatively large workpieces, it is not easy to design welding lines for split-point welding to achieve the welding effect, which can be spot-welded at multiple points at the same time. Cutting and sealing Using the working principle of ultrasonic instantaneous vibration to cut ...

The solder joints of ultrasonic welding should have high joint strength and qualified surface quality. In addition to the obvious extrusion pits and protrusions on the edge of the solder joints on the surface, attention should be paid to the surface conditions of the solder joints in contact with the upper sonotrode. , Cracks and partial unfusion are not allowed. Therefore, the selection of ultras...

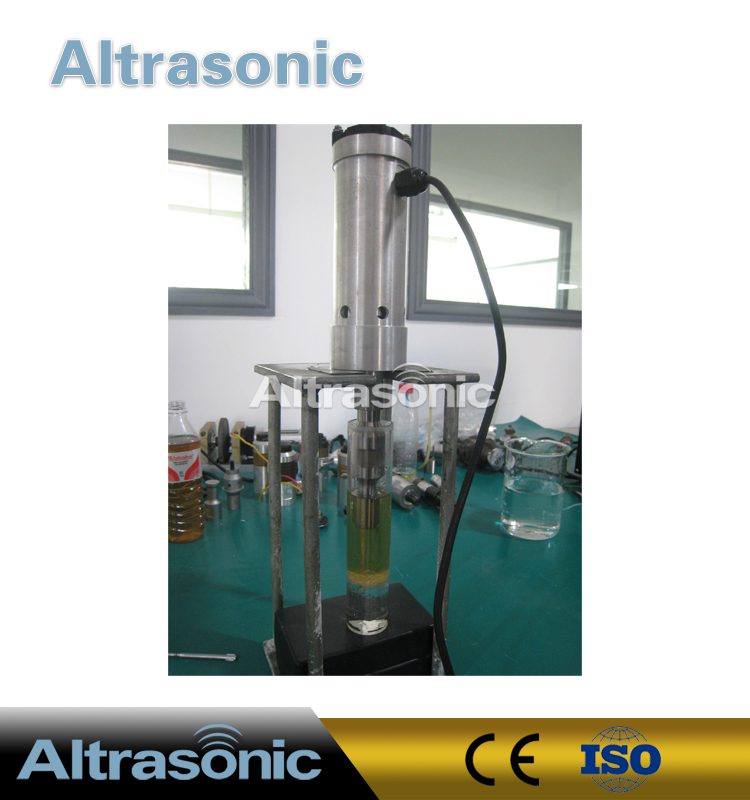

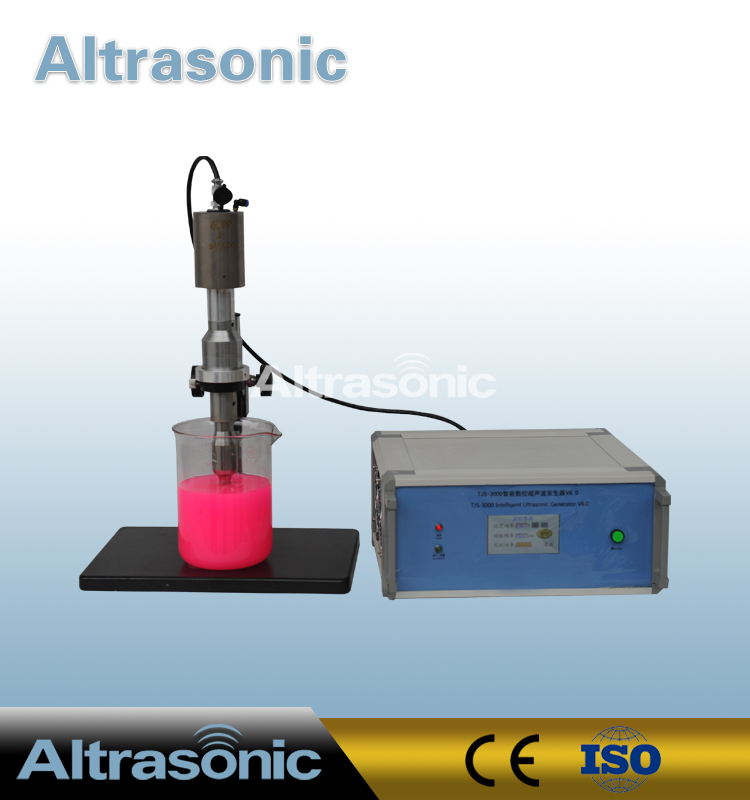

The application range of ultrasonic cell crushers is becoming more and more extensive, and a variety of novel ultrasonic cell crushers that have been continuously improved and improved are replacing old-fashioned equipment that has been on the market. In the past 10 years, the ultrasonic cell crusher is developing in two aspects. One is that various types of multi-cylinder or transmis...

The ultrasonic cell crusher uses the dispersion effect of ultrasonic waves in the liquid to cause the liquid to produce cavitation, thereby breaking the solid particles or cell tissues in the liquid. Ultrasonic cell crusher is a kind of elastic mechanical wave in the material medium. It is a form of fluctuation, so it can be used to detect the physiological and pathological informati...

1. Welding method: The welding head vibrating with ultrasonic ultra-high frequency under moderate pressure makes the joint surface of the two plastics generate frictional heat and melt and join instantaneously. The welding strength is comparable to that of the main body. Suitable workpieces and reasonable interfaces are used. The design can be watertight and airtight, and avoid the inconvenience c...

The welding structure must meet specific requirements for use, which is an important basis for material selection and welding process formulation. Welded structure manufacturing engineers and technicians must understand the basic characteristics of welded structures. Compared with the riveted structure, the welded structure has the following advantages: 1. Compared with riveted joints, the load-be...

Plastics that can be welded usually include materials such as PE, PP, nylon, and PET. At present, plastic welding methods use more ultrasonic welding, friction welding, vibration welding, laser welding, induction welding, high frequency welding, hot air welding and hot plate welding. There is no better, only suitable. The advantages and disadvantages of these welding methods are described below. T...

The working strength of the ultrasonic welding machine can never reach the strength of one-piece molding, it can only be said to be close to the strength of one-piece molding, and the required standard of its welding strength must rely on multiple cooperations. What are these cooperations? Because there will be two situations in the operation of ultrasonic welding machine: 1. High heat ener...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp