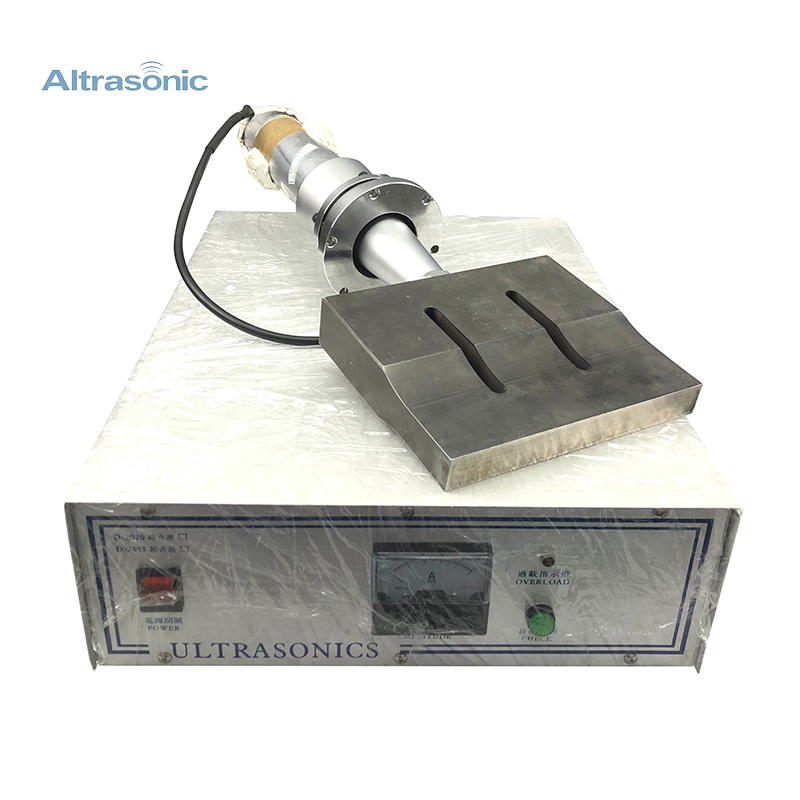

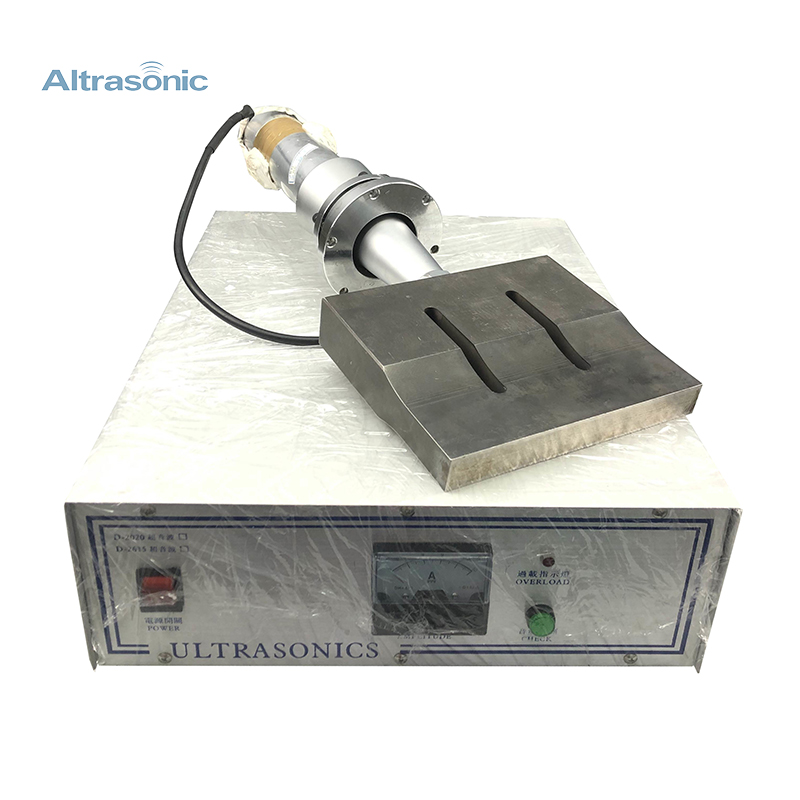

In the ultrasonic welding process, the impedance matching of the ultrasonic plastic welding machine is very important. During the ultrasonic work, it is often encountered that the equipment does not have enough power to complete the process. The reason is that the best load of the ultrasonic power supply is equivalent to the transducer The resistance is not matched, resulting in the ineffective tr...

The performance of plastics affects the effect of ultrasonic welding. The ultrasonic weldability of plastics depends on the plastic's attenuation ability to ultrasonic vibration and the level of melting temperature, as well as physical properties such as elastic modulus, impact resistance, coefficient of friction and thermal conductivity. Generally speaking, the greater the hardness of plastic pro...

In ultrasonic welding, air pressure transmits ultrasonic vibration to the weldment through the sonotrode. Different materials determine the amount of pressure required during welding. Choosing an appropriate air pressure value has a very important impact on the welding result. The following editor will lead you to understand the effect of the lower air pressure on ultrasonic welding. If the air pr...

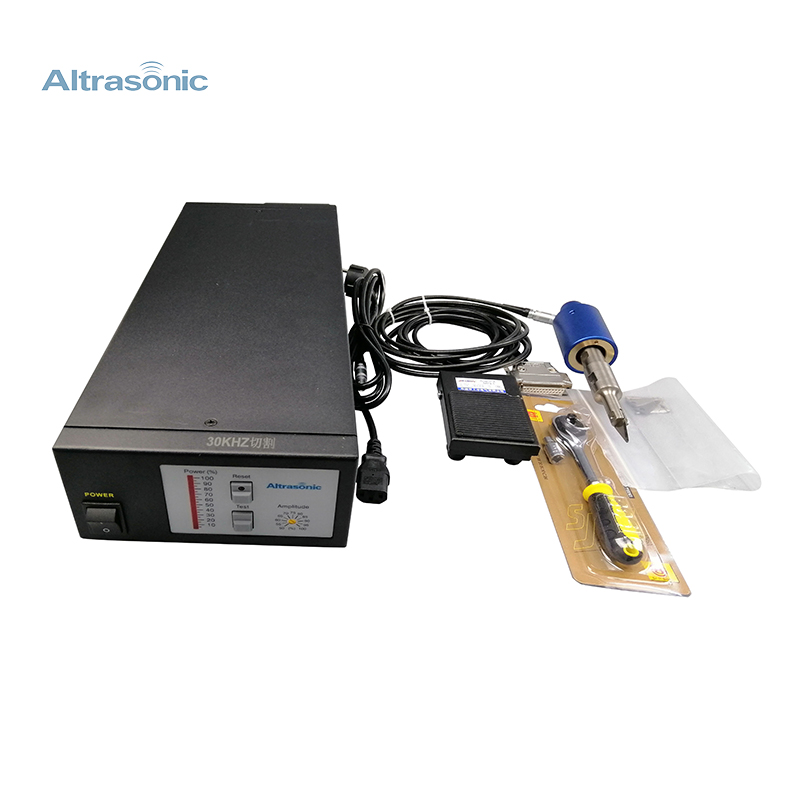

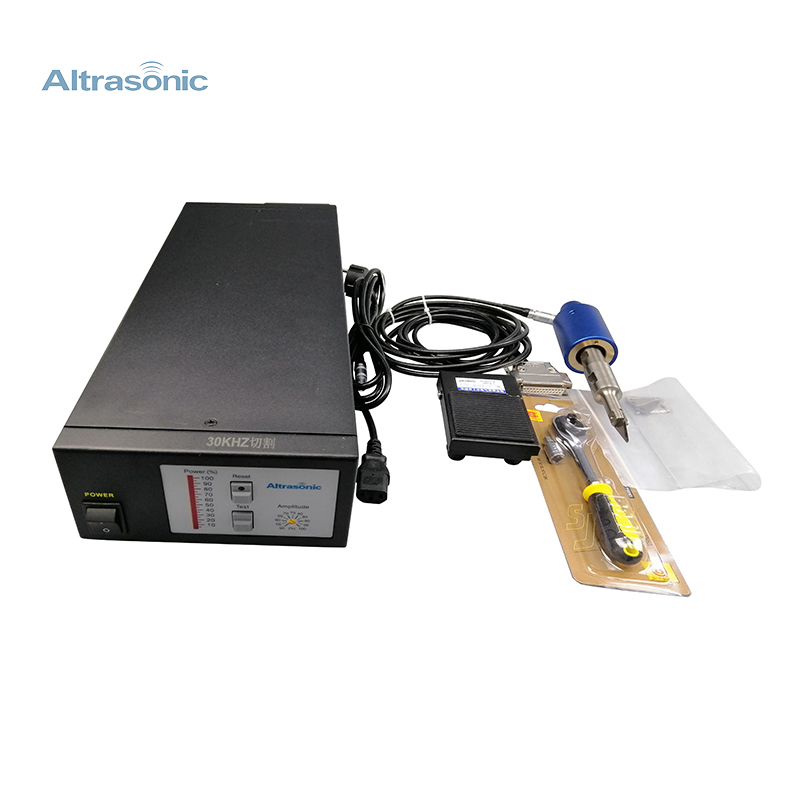

Cutting principle Ultrasonic cutting is an activity involving various objects that rely on ultrasonic energy. Unlike other cutting methods, the edge is very blunt. Once the cutting program is completed, it will generate a fusion effect. Electrical pulses are sent to the cutter, causing you to even see the micro vibration. The material will be heated, softened or even melted, so the actual cut does...

Ultrasonic cutting technology uses audio to generate vibration. The high-frequency vibration generated by the ultrasonic cutting knife makes the cutting blade of the machine. The high speed of these vibration means that the blade moves back to thousands of times per second, which makes the cutting knife to easily remove the material, even if it is more difficult to cut the material. This is becaus...

What should I do if the screw hole of the ultrasonic mold is slippery and the screw is broken? The ultrasonic mold is used for a long time, it is easy to produce the phenomenon of screw hole slippage or ultrasonic mold screw fracture. When the above phenomenon occurs in the mold, you must not continue to use it until it is processed. If the screw is broken, replace the connecting screw, it is best...

In the ultrasonic welding process, the amplitude of the ultrasonic welding equipment plays a decisive factor in the impact of welding. Usually, we select the appropriate amplitude range according to the products to be welded. Next, Nico’s editor will lead you to learn some ultrasonic welding knowledge. Amplitude is one of the very important parameters in the ultrasonic welding machine. It has a de...

For the concept of hot plate machine and hot melt machine, everyone may be a bit vague. There must be differences between them, but at the same time, there are also common points. Today Nico’s editor will lead you to learn the related welding of hot plate machine and hot melt machine. Knowledge. The hot plate machine adopts a plate-drawing structure, and the heat of the heating plate is transferre...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp