In the ultrasonic welding of plastic products, it is a very common problem that the joints of the upper and lower shells of the products are misaligned. Why does the product appear to be misaligned? There are design problems of the product itself, the structure of the ultrasonic mold, and the debugging of the ultrasonic machine. However, in general, the product itself has a good positioning functi...

Ultrasonic welding machine mold is the part of ultrasonic energy output. There will be different treatments on the surface of many ultrasonic welding machine molds. The final effect of the surface treatment is to make the mold wear-resistant, corrosion-resistant, increase hardness, and increase aesthetics. First of all, ultrasonic welding machine molds mainly use three types of materials to make s...

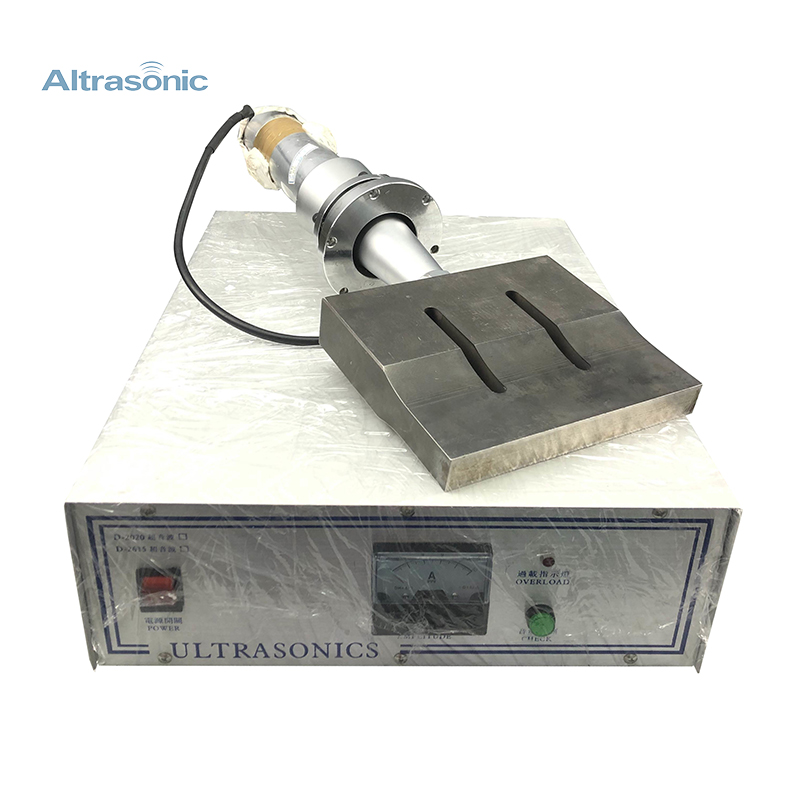

How to install and adjust the ultrasonic mold? We will all encounter it when replacing the ultrasonic mold. The editor will share some knowledge of ultrasonic welding with you below. 1. Install the mold 1. First wipe the transducer (CONE), mold (HORN) and connecting screw with alcohol or gasoline, and then smear the connecting screw, transducer and mold with a thin layer of yellow grease before we...

Why is the ultrasonic welding machine's welding unstable? What should I do if the welding is normal for a while and abnormal for a while? There are many reasons for the unstable welding of ultrasonic welding machine: 1. Whether the voltage is stable; 2. Whether the air pressure is stable; 3. The frequency deviation of the mold for a long time leads to unstable welding; 4. The machine has been used...

In the ultrasonic welding process, there are often scars, indentations, fractures or cracks on the surface of the product. At this stage, the ultrasonic plastic welding process has been applied to all walks of life due to its high efficiency, safety, and environmental protection. On the one hand, due to its unique material, when ultrasonic vibration acts on plastic parts, the surface of the produc...

1. Misunderstanding of ultrasonic output power The ultrasonic output power is the same as the diameter and thickness of the piezoelectric ceramic sheet, material, and design process. When the transducer is shaped, the maximum power is also finalized. It is a complicated process to measure the output energy. It is not that the larger the transducer, the more power tubes used in the circuit, the gre...

The ultrasonic drilling and milling machine can greatly reduce the cutting force, reduce the frictional heat, increase the service life, and reduce the surface roughness value of the machined. First, in the drilling and milling process, the tool head is not always in contact with the workpiece, but in a regular contact and separation state; the regular pulse impact cutting force replaces the conti...

1. Process misunderstanding of welding workpiece Ultrasonic energy is instantaneous. The welding line should be a point or line and the distance of transmission must be in line with the ultrasonic welding method. Some people think that as long as it is a plastic material, no matter how the joint surface can be welded well, this is a wrong understanding. When the instantaneous energy is generated, ...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp