During the ultrasonic Cut&Seal process, materials are welded and simultaneously cut in one step. The ultrasonic Cut&Seal process is used everywhere, where it is important to seal edges as they are being cut or in order to make a process more efficient by combining the two steps and avoiding subsequent punching. For example, in the packaging industry, the sonotrode table is used, with which...

Ultrasonic energy acts on the medium, which will cause high-speed and subtle vibrations of the particles, resulting in changes in mechanical quantities such as speed, acceleration, sound pressure, and sound intensity, which will cause mechanical effects. Ultrasound is the propagation form of mechanical energy, which is related to the wave process and will produce a linear effect of vibration. When...

The strength of ultrasonic welding is closely related to the quality of our welding products. In the welding process, the quality of the products welded under different strength conditions is uneven. When using ultrasonic welding, the following phenomena occur. For different reasons, the welding data should be adjusted in different ways. 1. When the product is too welded, the cause may be: too ...

Ultrasonic welding can weld all hot-melt plastic products, so can acrylic (acrylic) materials be welded by ultrasonic technology? Acrylic and acrylic ultrasonic welding is possible. Acrylic ultrasonic welding has a very good effect. It is often used as a box, bottle bottom cap, etc. It is proved by welding experiments. Acrylic (acrylic) material characteristics: 1. Crystal-like transparency, ...

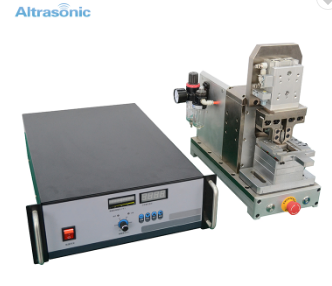

Ultrasonic cutting machine is a kind of equipment that uses wave energy for cutting processing. Its characteristic is cutting without cutting edge. In other words, it does not require traditional edges. Traditional cutting is to use sharp edges to press the cut material. This pressure is concentrated on the edge, and the pressure is great. If the shear strength of the material being cut is exceede...

The function of the welding head of the ultrasonic welding machine is to manufacture specific plastic parts to meet the requirements of the shape and processing range of the plastic parts. The transducer, welding head, and welding head are designed according to the half-wavelength of the working ultrasonic frequency, and the size and shape should be specially designed. Any change may lead to chang...

When an object vibrates, it makes a sound. Scientists refer to the number of vibrations per second as sound frequency, in Hertz. When the vibration of the object exceeds a certain frequency, that is, higher than the upper limit of the hearing threshold of the human ear, the human can not hear it. This kind of sound wave is called "ultrasonic." With the emergence of ultrasonic welding machine, usin...

The hot plate welding machine mainly uses a temperature-controlled heating plate to weld plastic parts. When welding, the heating plate is placed between the two plastic parts. When the workpiece approaches the heating plate, the plastic begins to melt. After the preset heating time, the plastic on the surface of the workpiece will melt to a certain degree. At this time, the workpieces are separat...

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp